Because the commercial success of an industrial project requires a solid process design

The transformation process yields a marketable product in a controlled and repetitive manner in accordance with the codes, standards and laws in effect. The product must also meet market expectations, and manufacturing costs must be lower than the selling price. Companies that run industrial production operations need the Seneca process package. This is an essential management tool for building a new plant or improving an existing one

BENEFITS THAT MAKE ALL THE DIFFERENCE

Our clients have said it loud and clear: developing the Seneca process package is critical to the successful completion of their projects. It converts their business objectives into the technical data that defines the basis of design, which all stakeholders rely upon until the plant is commissioned.

An optimum level of control

The Seneca process package gives you technical control over the success of your project, and lets you manage the associated risks. It defines all process unit operations and the basis of safety. It is used as a reference by technical managers so they can steer the project to success. Each and every decision is pertinent, because it aims for technical success.

Efficient teams

Process design enables all your project resources to quickly understand the issues, the scope, the objectives, and the deliverables. Your work teams become more proficient, more mobilised, and more productive.

Smooth running

The Seneca process package is a highly effective communication tool as well as a management tool for technical success. It lets you make the best decision quickly. It lets every stakeholder understand the risks and control them better. Problems are quickly resolved as they arise, without affecting the budget or the schedule.

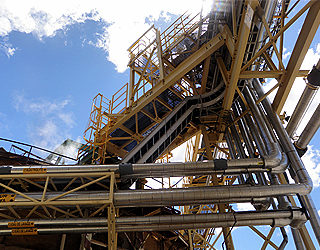

Seneca is a world-class engineering firm specialised in processing.

Processing in brief

An industrial process is the transformation of a natural or synthetic raw material into a new form, with the aim of manufacturing a finished product which subsequently goes to market. Transformations can be the result of an extraction, a control, or a purification process. Not many people see a material’s processing since it generally happens in closed environments, such as inside basins, pipes or tanks. As a result, it is difficult to understand, imagine and optimize these processes. Process engineering meets today’s industrial challenges, including the following: