WE USE COOKIES ON THIS SITE.

Our cookies and those of our partners help enhance your website experience and analyze its usage. To learn more about cookies, please consult our privacy policy.

Keep

evolving.

WHO WE ARE

We Help Companies Evolve

At Seneca, we are committed to thriving in a world of constant change. By embracing sustainable practices and advanced technologies, we make companies safer and more productive. With a firm belief in the power of ideas, we passionately drive transformation, designing and delivering industrial projects that create positive and lasting impacts. Our goal is to propel our clients toward lasting success.

We are Seneca.

We are Seneca.

WHAT MAKES US STAND OUT

Comprehensive Support

Every project is unique. With a comprehensive approach, we guide our clients through every stage, from the design to the operation of their infrastructure, regardless of their commercial maturity. Leveraging our expertise, we offer integrated management and precise follow-up to deliver impactful projects. Our goal is to create sustainable solutions that align with our clients' objectives and address the challenges of tomorrow.

WHAT WE DO

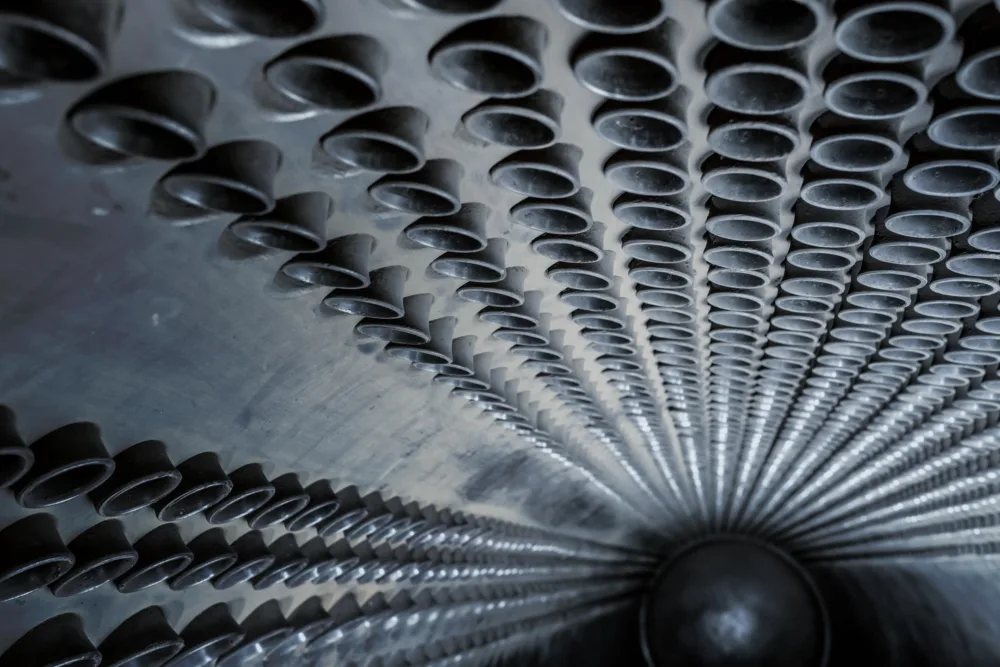

Beyond Engineering

Our value lies in our commitment to ensuring the success of industrial infrastructures through a comprehensive range of services tailored to the unique needs of each project. From design to construction, we develop innovative and sustainable solutions that address our clients’ most pressing challenges. Our mission is to simplify complexity, delivering straightforward answers to even the most intricate problems.

WHERE WE EXCEL

Our Activity Sectors

The world is constantly evolving, and businesses must adapt to keep pace. By blending expertise, experience, and technological curiosity, we deliver thoughtful, reliable solutions that drive industrial evolution sustainably while addressing immediate needs. Our experts tackle the unique challenges of each sector with a thorough and creative mindset. Discover all our areas of expertise.

SLIDE